Manufacturing Services

Manufacturing

We supply a wide variety of machine knives and punches

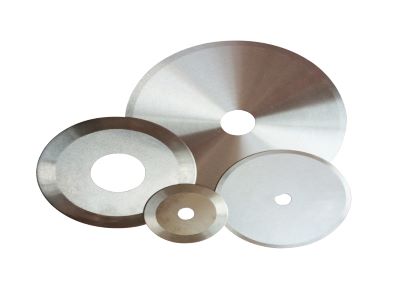

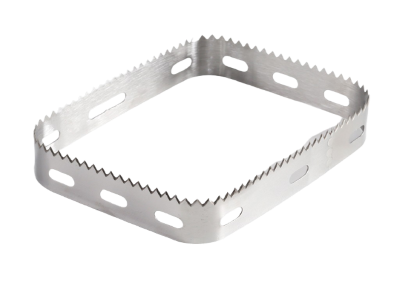

BLADES BY SHAPE

Circular blades, Slitting blades, Serrated blades, Scalloped blades, Straight blades, Pointed Tip blades, Toothed blades, Tray-sealer knives, Bowl choppers and many more.

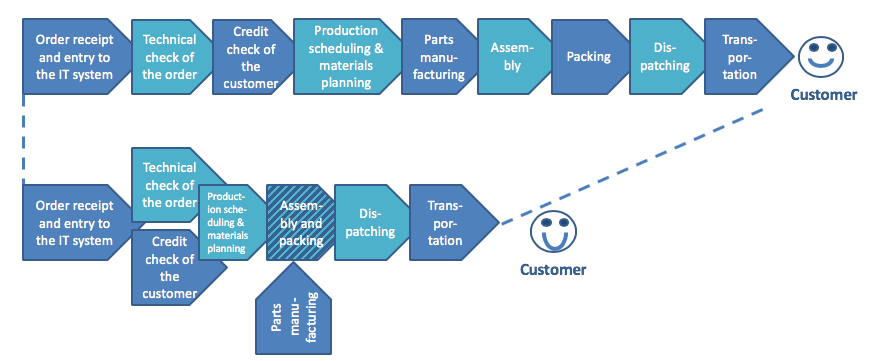

Manufacturing Process

Raw Materials

Are sourced from primary steel manufacturers of certified quality.

Laser Cutting

To create a smooth cut, a laser beam melts the material at its surface and through its cross-section, rather than physically cutting through the material.

Heat Treatment

We source the collaboration of external specialized and certified companies for vacuum and salt hardening processes.

Grinding

Allows us to carry out all the mechanical processes necessary to make our products internally with a high standard of quality.

Surface Treatments

We employ specialized and certified external companies for all types of surface coatings: PVD (TiN, TiCN, DLC) and Teflon.

Quality Control

Each product is controlled by specialized personnel using modern measuring instruments.

Packaging

Thorough final tests, accurate packaging and after sales service, complete the production cycle.

LEAD TIME AND TURNAROUND TIME REDUCTION

We understand your machine blades and knives play an important role in your daily production, that is why we make sure you have them when you need it and not a minute later.

Our company strives for fast turnaround times because we understand that without your machine knives, you likely do not have a finished product to sell.